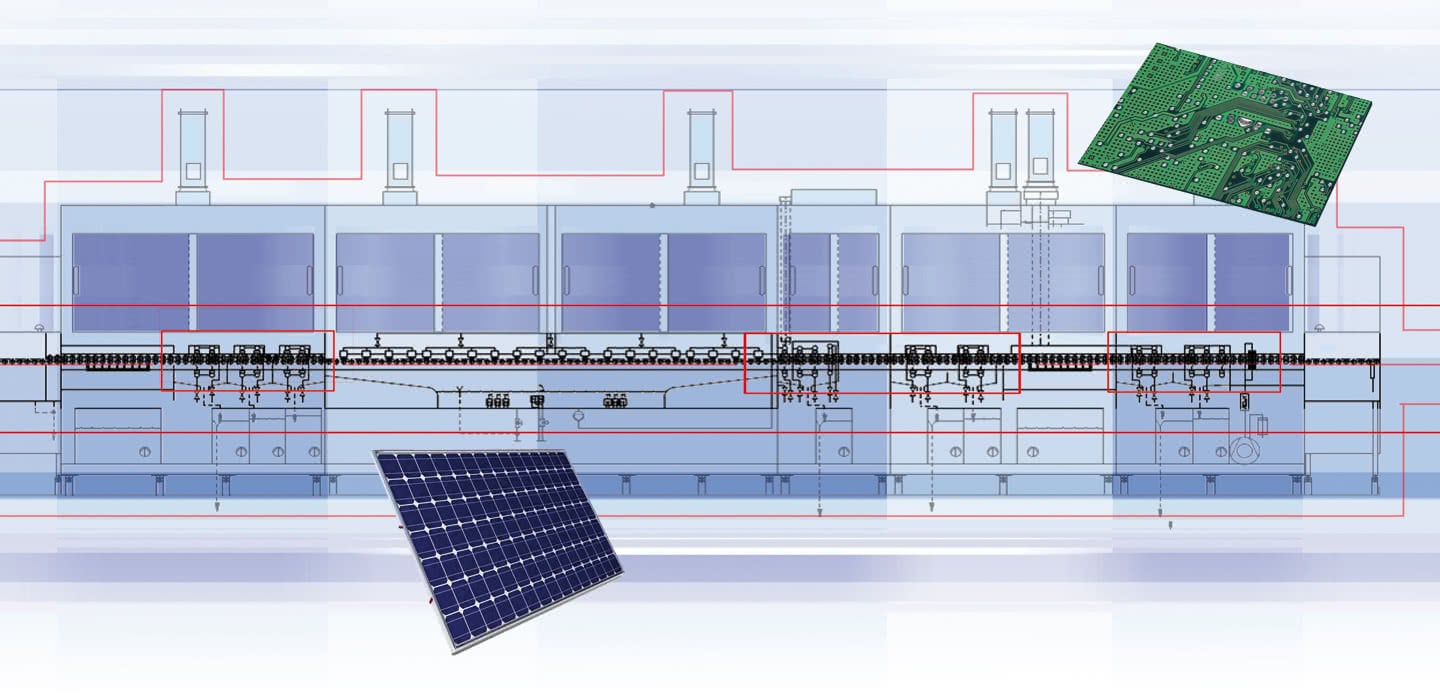

Printed Cleaning Board (PCB) Cleaning Equipment

Nozzles are used in several complex manufacturing steps of printed circuit boards (PCB) production cleaning where equipment and parts must be entirely free from particulates. After the sawing process, wafers must be cleaned so that no residue is present, since these are produced for microelectronics, photovoltaics and microsystems

Lechler nozzles in photovoltaic and printed circuit boards industry

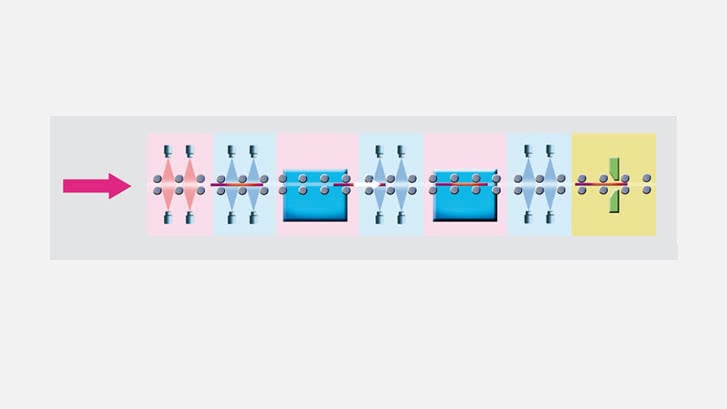

Nozzles for alkaline texturing

- Process specific application of flat fan nozzles in several series-connected modules.

- Preferred application of nozzles made of PVDF due to their resistance to chemicals used in the individual processes.

Nozzles for wafer moistening

- Application of hollow cone nozzles for moistening the wafers following the sawing process.

- Hollow cone nozzles produce a fine spray mist that settles on the wafers. This ensures that no impurities dry onto the wafer, thereby also ensuring an efficient wafer production process.

Circuit board manufacturing

- For the process steps of developing, etching and stripping regarding manufacturing circuit boards, different nozzles are applied in a typical inner layer line.

- An example for the nozzles applied here is the series 646 nozzles with bayonet quick-locking system.

Highlighted Products

Nozzles for alkaline texturing

Series 652.xxx.8H.03

Especially low flow rates. Parabolic liquid distribution.

Applications: Belt lubrication, moistening, spraying of food products, moisturization of rollers, oiling, lubrication of metal sheets.

Nozzles for wafer moistening

Series 220

Extremely fine, fog-like hollow cone spray.

Application: Disinfection, humidification, cooling.

Series 490/491

Non-clogging nozzle design. Stable spray angle. Particularly even liquid distribution. Series 490/491 represents a new generation within the axial-flow full cone nozzles product group. These nozzles were developed using state-of-the-art-design and simulation methods (CFD).

Applications: Cleaning and washing processes, surface spraying, Container cleaning, foam precipitation, degassing of liquids.

Series 646

Quick and easy assembly with bayonet quick release cap. Adjusted spray direction. Uniform liquid distribution.

Application: Belt cleaning, surface treatment, spray cleaning, coating processes.

For additional products, please refer to suggested literature.