A global ice cream manufacturer and the Lechler Indonesia Team conducted a trial to minimize the water consumption of the CIP process and improve the cleaning quality. To optimize the CIP process, Lechler XactClean HP+ nozzles were used instead of rotating cleaning nozzles. In order to meet their very ambitious sustainability program, the ice cream manufacturer is focusing on increasing efficiency to reduce the water footprint wastewater pollution.

PROJECT GOALS

- Reduce water consumption and wastewater pollution in the CIP

- Improve cleaning quality

- Reduction of the water footprint

CHALLENGES

- Demonstration runs on-site to prove Lechler's proposal

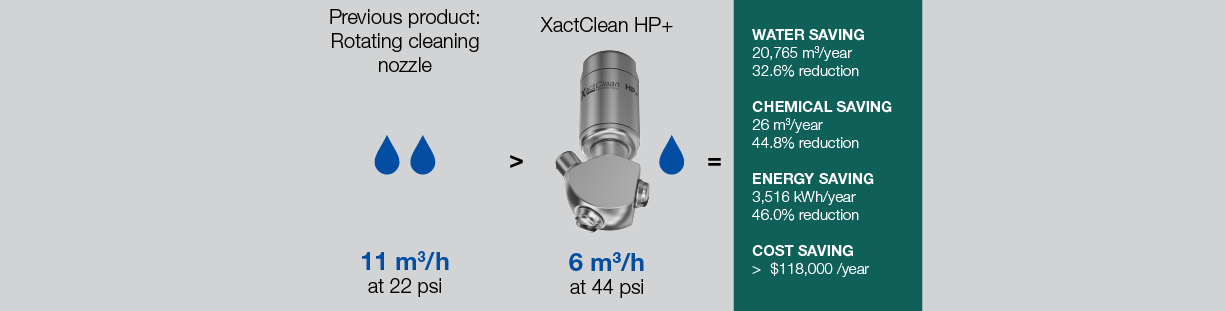

- Comparison of the performance results of the existing rotating cleaning nozzles (competitive product) with the Lechler XactClean HP+

SOLUTION

- Replacing the rotating cleaning nozzles with Lechler XactClean HP+ nozzles, series 5S5

- Achievement of the objectives defined in the client's sustainability program

CUSTOMER BENEFITS

- Achievement of significant savings in water, energy and chemicals

- Shortened cycle time of the 3-stage CIP process

- Annual cost savings potential of more than $118,000

- Return on invest time of less than 2 years