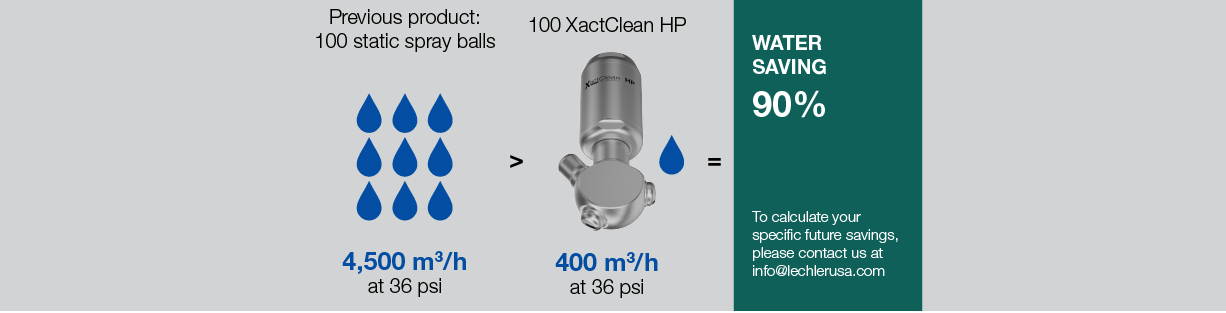

A large brewery with several locations in Italy partnered with Lechler to optimize their CIP for 100 tanks. Prior to the optimization, static spray balls were used for cleaning.

PROJECT GOALS

- Reduce water consumption in the CIP

- Increase sustainability

- Improve efficiency

CHALLENGES

- Detailed identification of technical requirements in several customer visits on site

- Creation of a draft to dimension the process based on Lechler's experience, including tests for effectiveness in several demonstration runs

SOLUTION

- Replacement of spray balls by Lechler XactClean HP nozzles, series 5S3

- Lechler TankClean software as a support for comparing the efficiency of spray balls and XactClean HP nozzles

CUSTOMER BENEFITS

- Achievement of significant savings in water, energy and chemicals

- Water savings achieved by the XactClean HP nozzles have a significant impact on the customer sustainability and financial targets