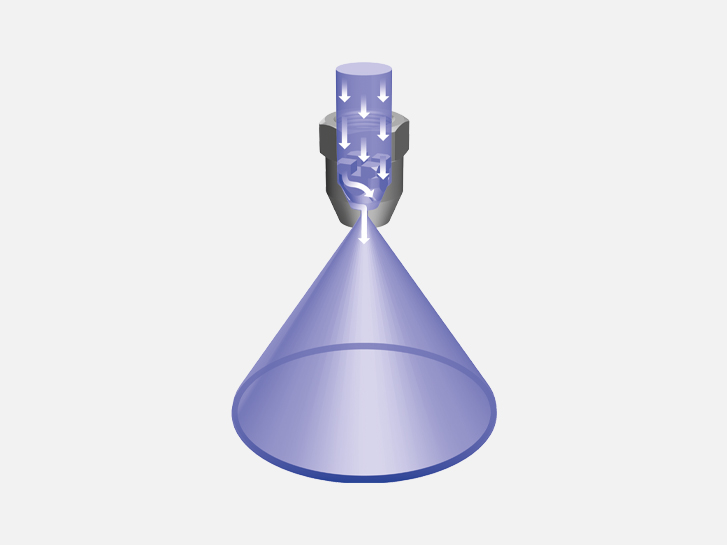

Hollow Cone Spray Nozzle

Hollow cone nozzles come in two styles: axial-flow and tangential flow.

Hollow cone spray nozzles provide a unique liquid distribution where the spray comes down in a ring-shaped distribution. Customers can obtain medium to the smallest water droplets for their particular application without having to worry about clogging. With Lechler hollow cone spray nozzles, you obtain superior design and strong materials to suit your process setup.

Applications for Hollow Cone Spray Nozzles

Full cone nozzles are very common in a wide range of applications due to their free cross section designs and clog resistance. Companies can use these nozzles when having low and high flow rates while reducing the amount of water that must be used, helping to conserve water and reduce energy costs.

These spray nozzles are used for cooling and gas scrubbing. They help reduce temperatures for work areas, machinery, and products to reduce damage and wear-and-tear of components. The nozzles also lower the amount of excess gas generated from combustion process to provide pollution control measures.

Other applications include washing processes. Hollow cone nozzles can remove dirt, grime, chemicals, and other particles from tanks, totes, conveyor belts, equipment, and products. They can be used with stationary and mobile equipment setups.

Dust control and fire protection environments can also benefit from the use of hollow cone spray nozzles. The spray nozzles interact with dust to prevent it from becoming airborne and makes airborne dust heavy to where it falls to the ground. For fires, the spray nozzles can remove oxygen and high temperatures to extinguish flames and help protect workers as well as equipment.

Criteria for Selecting Hollow Cone Spray Nozzles

Customers should consider hollow cones nozzles depending on flow rates and how the liquid will be supplied to the nozzle. Hollow cone spray nozzles come in axial-flow designs, where the liquid flow comes straight down into the nozzle. They also come in tangential setups (sideways flow). Axial flow nozzles have fine and small droplet sizes allowing for better atomization of liquids, while tangential flow nozzles provide coarser droplets.

Another factor to consider is the spray angle. Axial flow offers 90-degree spray angles and tangential flow provides up to 130 degree angles. The spray angle can be vital for processes where you need the liquid to reach specific areas and provide even coverage.

Types of Hollow Cone Nozzles

Axial-Flow Hollow Cone Nozzles

- Droplet size

- Narrowest free cross sections

- Maximum spray angle: 90°

Tangential-Flow Hollow Cone Nozzle Design

- Coarser droplets than axial-flow hollow cone nozzles

- Large narrowest free cross-sections

- Wide spray angles up to 130°

- Clog-resistant

Why Choose this Spray Pattern Over Others?

Hollow cone spray nozzles are often desired when needing the smallest droplet sizes available that other nozzles cannot provide. They are also considered for applications where space is an issue, as tangential hollow cone spray nozzles can accommodate areas that have small clearance. These nozzles work with both low and high flow rates to provide you with a range of different options.

Choose Lechler's Spray Nozzles

Lechler spray nozzles are designed to accommodate your application and equipment setup as we provide durable and strong materials that resist clogging. Obtain superior droplet distribution and liquid flow control with our hollow cone spray nozzles. Contact our company today so we can help you find the spray system products for your operations.