Spray Facts on Viscosity

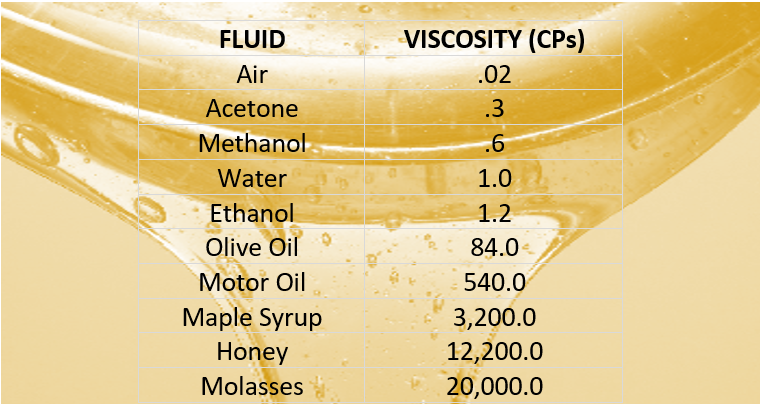

Viscosity is the thickness of a fluid and is measured by the resistance to flow. Nozzle performance charts are based on water, which has a viscosity of 1 cP. Viscosity is probably the most significant of all liquid properties because it can vary over an extreme range.

Examples of Viscosity

Viscosity & Nozzle Limitations

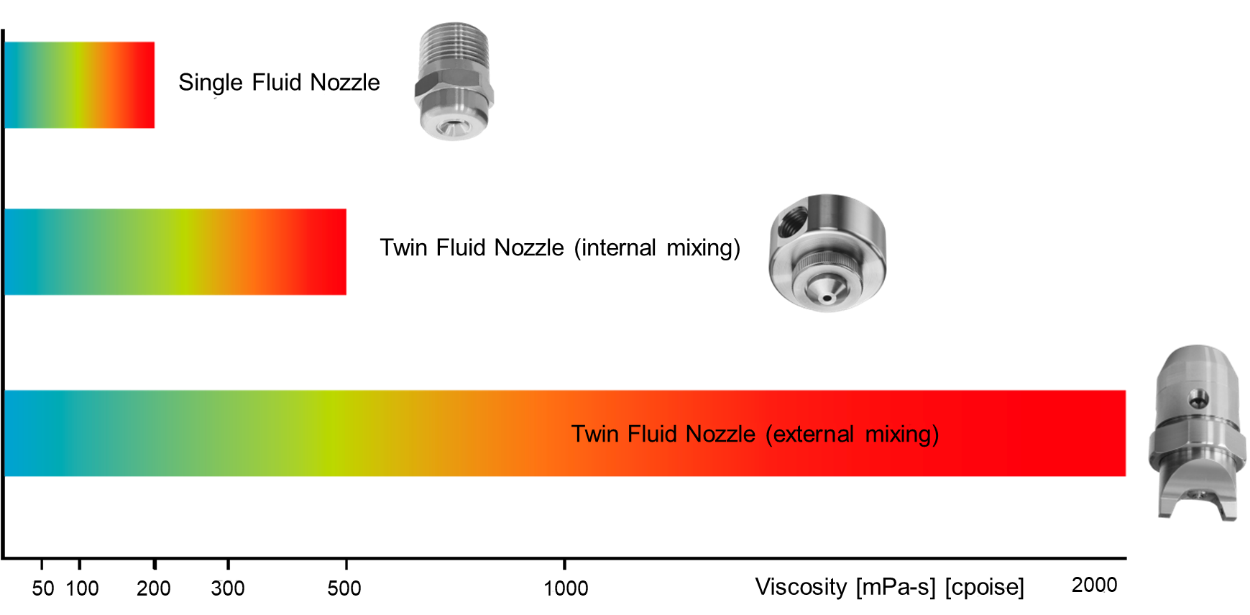

The viscosity of fluid can have various effects on nozzle performance and this is why different nozzle types have viscosity limits. In the chart below, single fluid nozzles work best with fluids having a viscosity of less than 100cP. Higher viscosities require more energy to atomize properly and twin fluid nozzles are recommended.

A twin fluid nozzle designed for internal mixing will mix a gas and fluid inside the mixing chamber. These nozzles are capable of spraying fluids less than 300cP. For viscous fluids greater than 300cP, an external mixing twin fluid nozzle is required. In this case, the gas and liquid mix at the nozzle orifice, producing larger droplets.

Effects on Performance

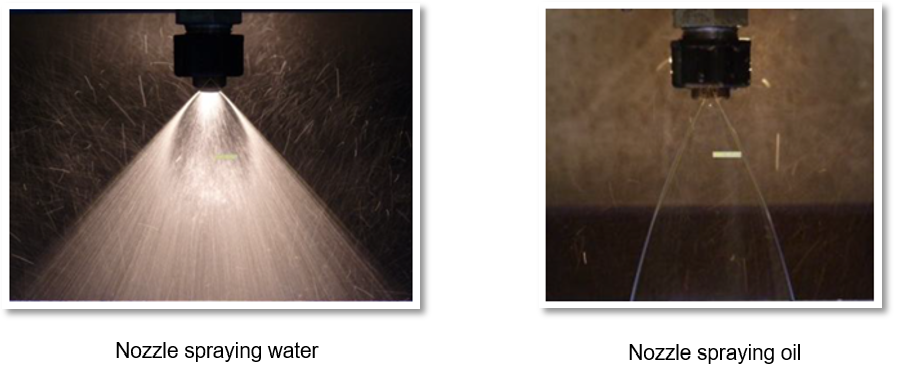

Liquid viscosity resists surface formation. If the viscosity is great enough, a nozzle may produce a mass of filaments instead of a spray. In the photos shown below, the same nozzle is used to compare two different fluids and viscosities being sprayed. The nozzle to the left is spraying water and on the right oil with an approximate viscosity of 111 cP. Fluids with a high viscosity, like oil, can reduce the spray angle and flow rate, which can result in poor spray coverage. This is why selecting the right nozzle can make all the difference in spray performance.

Temperature also affects viscosity because at higher temperatures the mass of the fluid can be reduced or thinned. Take for example, honey, which is fairly viscous. It will flow, slowly, in response to the force of gravity. When removed from the refrigerator, it will flow very slowly, and with a few seconds in the microwave, it will flow much more easily, and swiftly. Therefore, viscosity of a particular fluid changes as temperature is increased or decreased.

Conclusion

If you’re considering spraying a fluid other than water, it is important to know the viscosity of the material being sprayed and the temperature. Nozzle testing is recommended so that you can be assured your nozzle is performing correctly. Lechler has over 25,000 nozzles to choose from and our nozzle experts can assist you in testing and selecting the right nozzle for your application.